Sustainable Anorthosite Solutions from Greenland for a Changing World

Anorthosite

Anorthosite is a versatile and sustainable resource serving multiple use cases across industries. In e-glass production, it offers superior electrical insulation with a reduced carbon footprint, catering to the aerospace, automotive, and construction sectors' growing demand for environmentally friendly materials.

When incorporated into plastics, anorthosite enhances product performance by improving anti-block properties, UV stability, flame resistance, and toughness, providing a durable and sustainable alternative to traditional additives.

Additionally, its application in phenolic friction resins for brake systems and as a greenspar in paints increases durability and reduces volatile organic compounds (VOCs) emissions.

Beyond terrestrial applications, Lumina's anorthosite is a valuable resource for lunar studies. Its similarity to lunar highland materials enables crucial academic research and simulation, facilitating the exploration of lunar geology and the potential for in-situ resource utilization in future space missions.

Lumina Sustainable Materials produces high-purity anorthosite from its Qaqortorsuaq mine in Western Greenland. Our products—refined to different grades and specifications—are used across industries including paints, coatings, glass fiber, fire-retardant materials, fillers, and cement alternatives. With low silica, high aluminum and calcium content, and no toxic by-products, Lumina's anorthosite offers a cleaner, more sustainable mineral solution for modern manufacturing.

Reducing Emissions Across Industries

In every application, Lumina’s anorthosite helps reduce overall carbon emissions. Whether replacing bauxite in alumina production, lowering energy requirements in fiberglass manufacturing, or serving as a low-carbon alternative to traditional fillers and cement materials, our product contributes to greener industrial processes. By enabling manufacturers to reduce energy consumption, cut emissions, and eliminate harmful by-products, we support a more sustainable value chain from mine to end product.

Applications:

E-glass

Utilizing Lumina's anorthosite to produce E-glass delivers exceptional electrical insulation and a smaller environmental footprint, through energy savings and CO2 reduction, making it a prime, eco-friendlier choice for the aerospace, automotive, and construction industries.

Plastics

Anorthosite additives improve the anti-block, UV stability, flame resistance, and toughness of plastics, offering a sustainable solution that bolsters the durability and functionality of plastic products while diminishing reliance on non-renewable resources.

Friction

Anorthosite augments the strength, durability, and compatibility of phenolic friction resins used in automotive and industrial brake systems, presenting a greener alternative to conventional materials and reducing environmental impact.

Paints & Coatings

Greenspar, sourced from anorthosite, is integrated into paints and coatings to significantly enhance durability and facilitate lower VOC emissions, promoting environmentally friendly practices within the coatings sector.

Lunar Studies

Lumina's anorthosite acts as a terrestrial counterpart to lunar highlands, fostering academic research and simulation studies that facilitate lunar geology exploration and potential in-situ resource utilization in forthcoming missions.

Mineral Wool

With its high aluminum and calcium content, anorthosite-based mineral wool provides excellent insulation with fewer impurities, perfect for energy-efficient building and industrial uses, thereby contributing to sustainability.

Products:

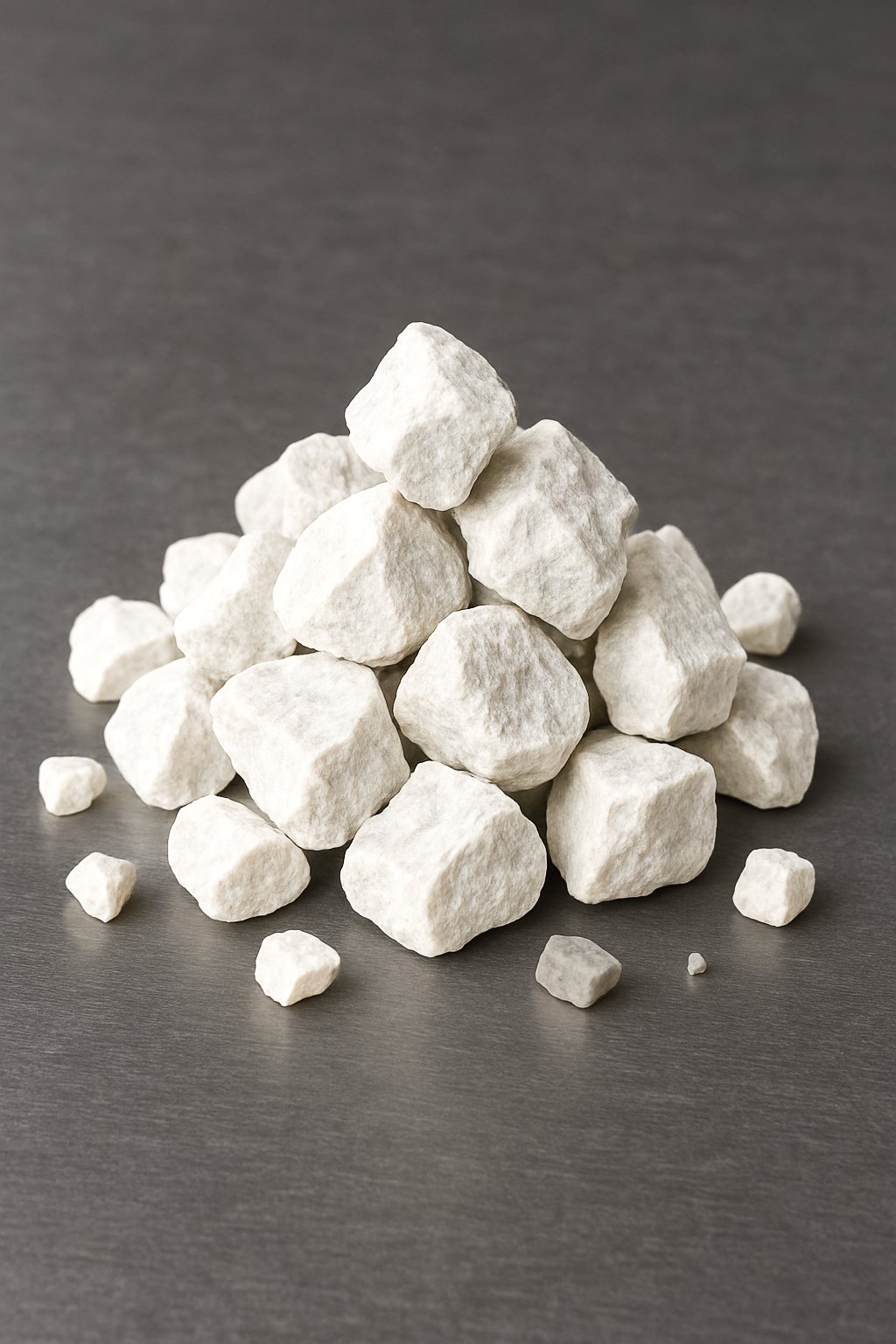

AnoRoq

AnoRoq is the run-of-mine anorthosite lump ore from the vast White Mountain deposit that is used as a feed for the Greenspar product line. High in purity, low in quartz, low in alkali, and with a highly consistent chemical composition.

Greenspar 2000

Greenspar 2000 is a high-purity, low-iron, sand-like anorthosite product designed for export for the global fiberglass industry or as a feed for the production of micronized feldspar for paints, polymers, and advanced material

Greenspar 60

Greenspar 60 is a high purity milled anorthosite powder with a 60µm top cut with very low binder demand, high-whiteness, and low quartz designed for highly durable and eco-friendly coatings and polymeric applications.

Greenspar 45

Greenspar 45 is a high purity milled anorthosite powder with a 45µm top cut with very low binder demand, high-whiteness, and low quartz designed for highly durable and eco-friendly coatings and polymeric applications.

Greenspar 15

Greenspar 15 is a high purity milled anorthosite powder with a 15µm top cut with very low binder demand, high-whiteness, and low quartz designed for highly durable and eco-friendly coatings and polymeric applications

Your Product

At Lumina, we believe in collaboration. Our team works closely with end-users to develop highly engineered anorthosite-based products that meet specific and demanding industrial needs. Whether it's particle size, purity, or performance, let's create the right solution for your application.

Customer Support Team:

For information regarding product pricing, volume-based offers, or delivery terms, please contact our Customer Support team directly. We are ready to assist you with tailored solutions to meet your specific needs.

-

Gerth Jacobsen

Head of Logistics | +299 84 32 17 | gerth@lumina.gl

-

Peter Madsen

Director of Operations | +299 493713 | peter@lumina.gl